The first comprehensive project of OSHW-UHU is to build a full open hardware analytical system by flow injection (FIA) including the impulsion and the injection systems and some type of detector.

Continuous flow analytical techniques are a powerful tools for determining the containing of samples because they are very sensitive, fast and configurable; enabling their adaptation for analyzing a broad quantity of chemical compounds and sample types. There are used in the food, water, pharmaceutical, sanity, agricultural, chemical industries and more; to check the products, process and raw materials quality, to environmental control of plants, surface water, soil, air, etc.

There are high performance equipments based on chromatographic techniques with the best analytical capabilities but commonly their requirements are more exigent (high pressure or vacuum conditions, gas needs, adequate facilities, trained staff). Furthermore, their price is very expensive both for acquisition and maintenance.

By other hand, the flow injection analytical techniques (FIA) works at low pressure, the modules that configures the equipment are less exigent and expensive and the flow channel is more configurable. Moreover, there are more sensitive and selective methods every day and the analytical capacity reached today by the FIA methods is comparable to the chromatographic ones.

Nowadays, the FIA methods are the best option for labs were competitive results are needed and the availability of founds is a major limiting factor. This is true especially if there are open source designs of modules that configure the FIA channel (impulsion system, injection valves and detectors). This is the late motive of our first project, to release a set of open source versions of the main components of a FIA system. Our intention is to provide easy and reliable designs, sometimes recycled materials will be used, and always the calibration and fine tuning methods required are provided.

PS: Pumping System; S: Sensor; T: Transducer

All these modules will be fully operative by it self, and they may operate manually (they have a control panel) or in remote mode (with a USB connection in the first version).

Open ISEmeter Project

Status: Beta, stable

|

|

|

|

Brief description

In this project, a new Arduino-based interface to read electromotive force (emf) for potentiometric detection is presented. This interface is the first of a series of sensors/transducers we will publish soon.

The interface has been fully designed with the open code philosophy and all documentation is accessible on web. The project includes the electronic design, the firmware loaded on Arduino and the Java-coded graphical user interface (GUI) to register data from a computer (PC or Mac). The prototype was tested by measuring the calibration curve of a detector. As detection element, an active PVC-based membrane was used, doped with cetyltrimethylammonium dodecylsulphate (CTA+-DS–). The experimental measures of emf indicate nernstian behaviour with CTA+ content of test solutions, as describes in the literature, proving the validity of the developed prototype.

Syringe pump system

Status: beta (hardware); alpha (software)

|

|

Brief description

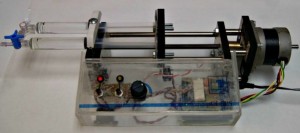

A syringe pump system is designed from scratch, describing how to build the mechanical layout, the electronics for manual control, the micro computer programming and the remote control procedure.

A communication protocol is implemented allowing USB remote control and fully programmable operation: linear flow

gradients and complex sequences, multiple pumps control for continuous flow or mixtures of fluids, and more. All documentation it’s fully web-accessible and both, hardware and software are open source. The final cost is very affordable and will save about 75% on commercially available devices with comparable features.

Performance is checked and it presents a syringe resolution of 0.004% respecting the nominal syringe volume, accuracy of 0.03% and relative standard deviation (RSD) below than 2% over the whole range of flow. When two syringes of 10 mL are used, the flow range goes from 7.72 mL/s to 0.26 µL/s.

By now, we are working in coding an app to control, calibration and synchronizing the pump from a remote computer by using the USB connection.

Motorized injection valve

Status: Alpha

|

|

|

Brief description

The module to insert a knowed ammount of sample in the flow is the injection valve. By using a loop of known volume, the injected quantity can be exactly controlled. Commercial automatic systems often use a stepper motor that, in addition to being expensive, requires complex electronics and programming. Our proposal is to use a DC motor, recovered from an old DVD player, to move the mechanical parts. This new approach requires the development of an appropriate controller that must provide for manual and remote operation. Electrical diagrams, part drawings and assembly instructions are available on the web.